Introduction

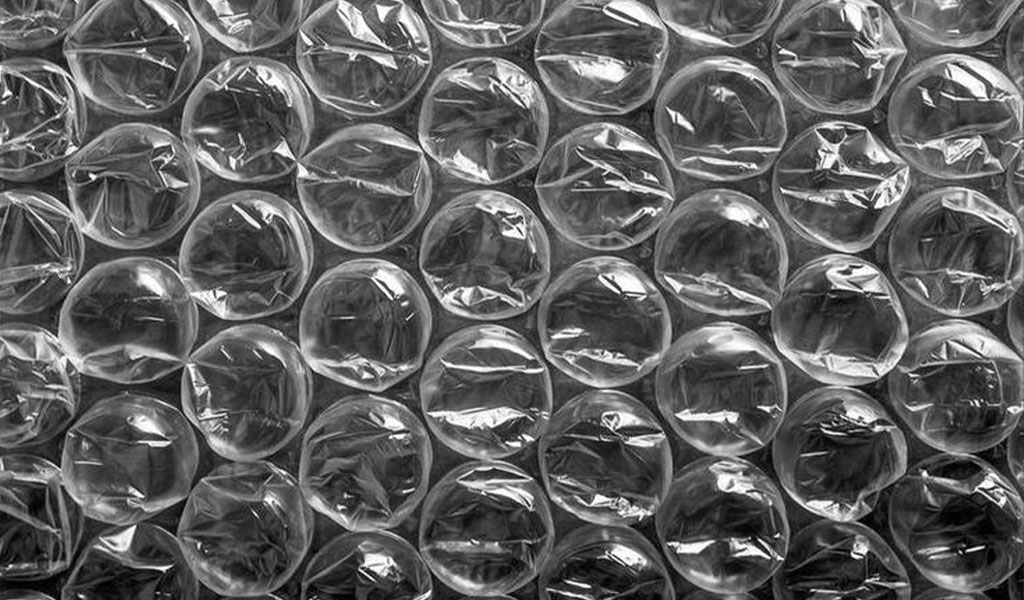

Bubble nylon is one of the most widely used packaging materials in the world, which is used in various industries due to its special characteristics such as impact resistance and protection of sensitive objects. These nylons, which are also known by different names such as bubble wrap or bubble wrap, consist of small air bubbles that are placed between plastic layers. In this article, we will introduce the types of bubble nylon and their applications.

History of bubble nylon

Bubble nylon was first invented in 1957 by Alfred Fielding and Mark Shawans. It was originally designed as a three-dimensional wallpaper, but over time it became one of the most widely used packaging materials. Today, various companies and industries use bubble wrap to package and protect their products.

Features of bubble nylon

- Protection of products: Bubble nylon protects objects from shocks and external pressure due to the presence of air bubbles.

- Lightness: This type of nylon is very light and does not add much extra weight to the packaging of goods.

- Flexibility: Bubble wrap is easy to wrap around different objects and because of its flexibility, it protects items of different shapes.

- Thermal insulation: This nylon can provide some protection from temperature changes, which is useful for packaging some temperature-sensitive products.

Types of bubble nylon

Bubble nylons are produced in different sizes and types, each of which has its own characteristics and uses. Below we review the main types of bubble nylon:

- One-layer and two-layer bubble nylon

Bubble nylon can be produced as one layer or two layers. In the two-layer model, there is more strength and impact resistance, and it is suitable for more sensitive products. - Small and large bubble nylon

Nylon bubbles are available in different sizes. Bubble wraps are used for packing small and delicate items, while coarse bubble wraps are suitable for larger and heavier products. - Antistatic bubble nylon

This type of bubble nylon is designed in a way that prevents the accumulation of static electricity and is very suitable for packaging electronic devices such as laptops, mobile phones and computer components. - Thermal bubble nylon

Bubble nylons with thermal insulation properties are used to package temperature-sensitive products, such as food, pharmaceuticals, and chemical products. - Colored bubble nylon

In addition to usual applications, these types of nylons can be produced in different colors for special packaging or advertising.

Applications of bubble nylon

- Packaging of electronic products: Due to the high sensitivity of electronic components to impact and static electricity, bubble wrap is used to protect these products.

- Fragile items packaging: Glass containers, pottery and other fragile items are packed with bubble wrap in transit so that they are not damaged by possible shocks.

- Use in the transportation industry: In the transportation of large and small goods, bubble nylon is used as one of the main materials for packaging and protection.

- Packing furniture and household items: When moving, bubble wrap is used to protect furniture, refrigerators, televisions, and other household items.

summary

Bubble nylon is widely used in various industries due to its unique features such as protection of sensitive objects, flexibility and high impact resistance. Bubble nylon is used in the packaging of electronic products, fragile items and even industrial products. Due to the variety of types of bubble nylon, it is possible to choose the right nylon for each type of product and special need.